The laboratory of catalysis and catalytic reactions is successfully operating at the Research Institute "Nanotechnology and New Materials". Currently, the laboratory is expanding its "powers" and has begun to create unique installations for oil and gas processing that are not inferior in their characteristics to world analogues.

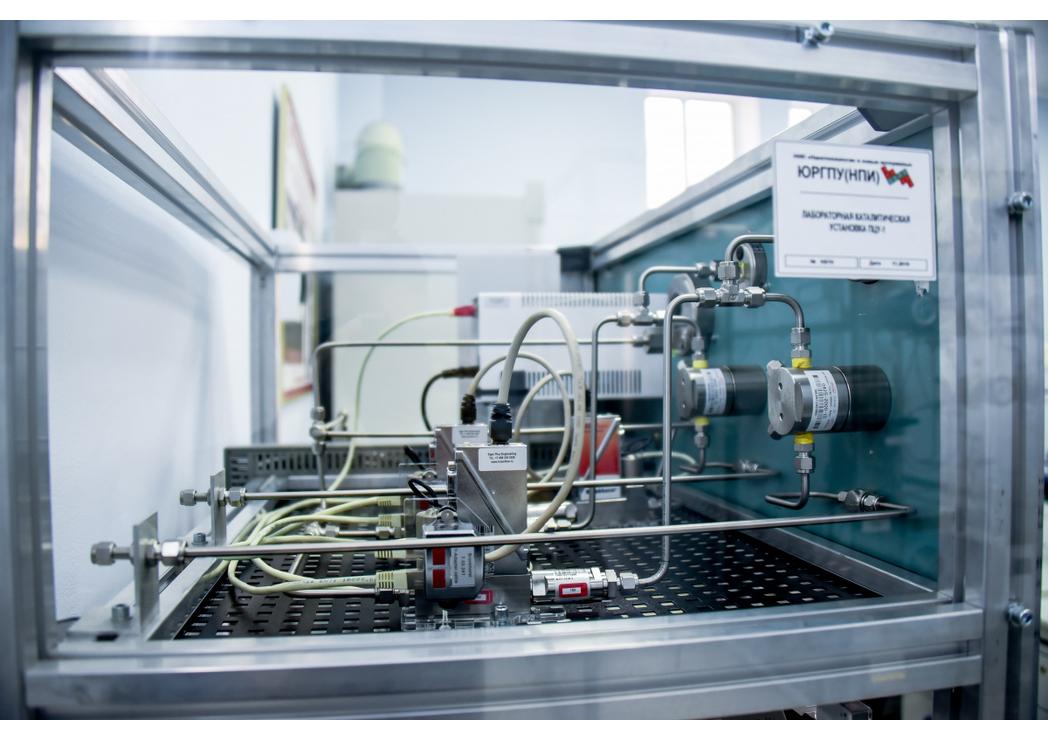

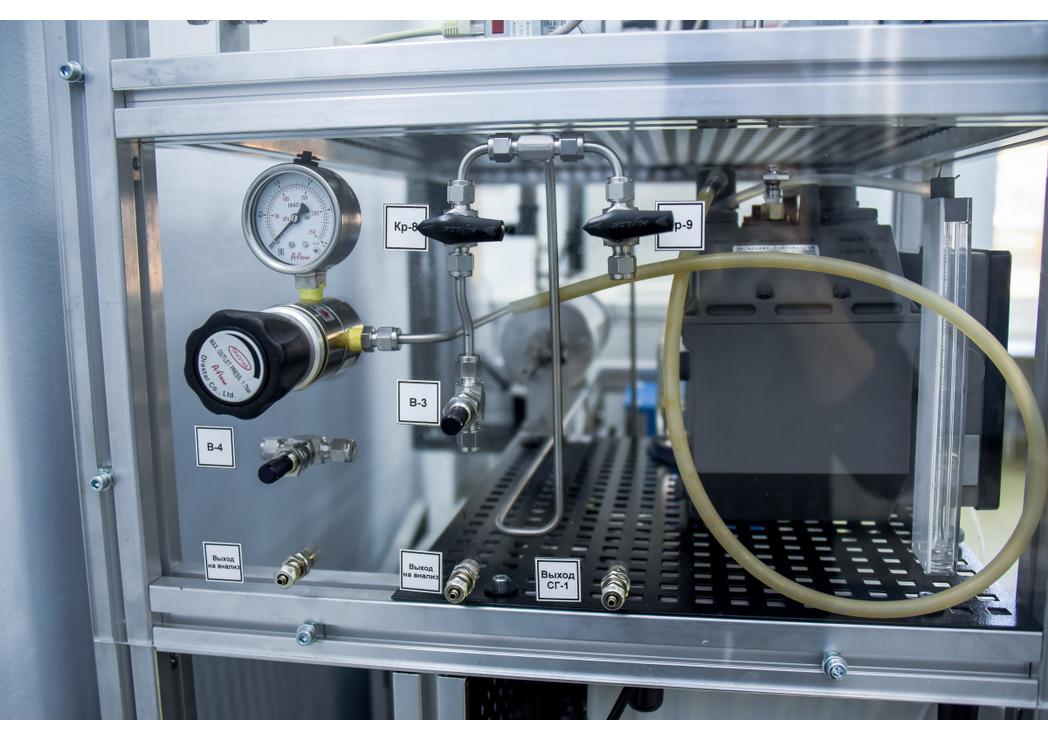

A group of our scientists has developed and created a universal laboratory catalytic unit PCU-1 (flow-circulation unit) designed for heterogeneous catalytic processes. It allows us to study the processes of oil refining (hydrotreating, reforming), methanol synthesis, various types of natural gas conversion (steam, carbon dioxide, partial oxidation). The installation provides gas circulation at a pressure of 100 atmospheres and high-precision supply of liquids and gases.

- The uniqueness of our installation is that it allows you to explore different processes: oil refining, catalytic cracking, reforming, isomerization, hydrocracking - all that allows you to improve the quality of fuels produced from oil, - explains senior researcher at the Research Institute "Nanotechnology and New Materials" Roman Yakovenko. - The advantages are obvious: all these processes can be investigated as close as possible to industrial conditions.

PCU-1 can be effectively used in scientific research in the field of heterogeneous catalysis, as well as in factory laboratories of the chemical and petrochemical industry, for the organization of laboratory work in chemical profile universities.

The information widely disseminated in narrow circles about the unique development of our scientists attracted the attention of professionals, and the Research Institute received an order from the Moscow Technological University to create four installations to equip their laboratories. The work has already been done and the first commercial product has been delivered!

It took about six months to manufacture four PCU-1 units. During this time, their creators have gained the necessary experience, as well as confidence that all subsequent products, provided production reaches the serial level, will be produced much faster.

It is worth noting that about ten researchers of the Research Institute "Nanotechnologies and New Materials", including young personnel, were involved in the work on the installation. It was the young people who were entrusted, for example, with 3D modeling. The popularity of the laboratory of catalysis and catalytic reactions in our university is growing, and even very young chemists - current freshmen - are already striving to join the exciting world of catalysis.