Heavy GTL

Synthetic waxes are a valuable raw material that is used in the food, cosmetic, defense industries, as well as as a raw material for the production of Group III+ isoparaffin oils. Of particular value is synthetic ceresin 100 - a fraction of n-paraffins with a melting point of 100 ° C (beginning of boiling at 760 mm Hg above 450 ° C).

The NTNM team, using significant experience in operating the industrial production of synthetic hydrocarbons, has developed a new technology for producing synthetic waxes from natural gases.

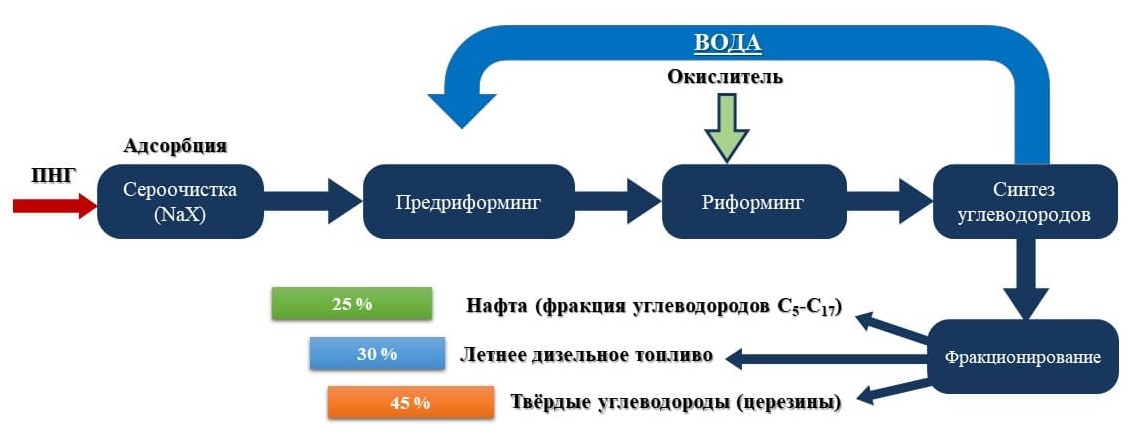

Key features of the technology:

- The use of steam carbon dioxide reforming to produce synthesis gas;

- Use of a new cobalt silica gel catalyst with high selectivity for waxes (up to 60%);

- Technological solutions for the intensification of hydrocarbon synthesis;

- A catalyst with a hierarchical porous structure for the production of isoparaffin oils from waxes.

Catalysts

To obtain synthesis gas, the technology uses industrial catalysts from NIAP-Katalizator.

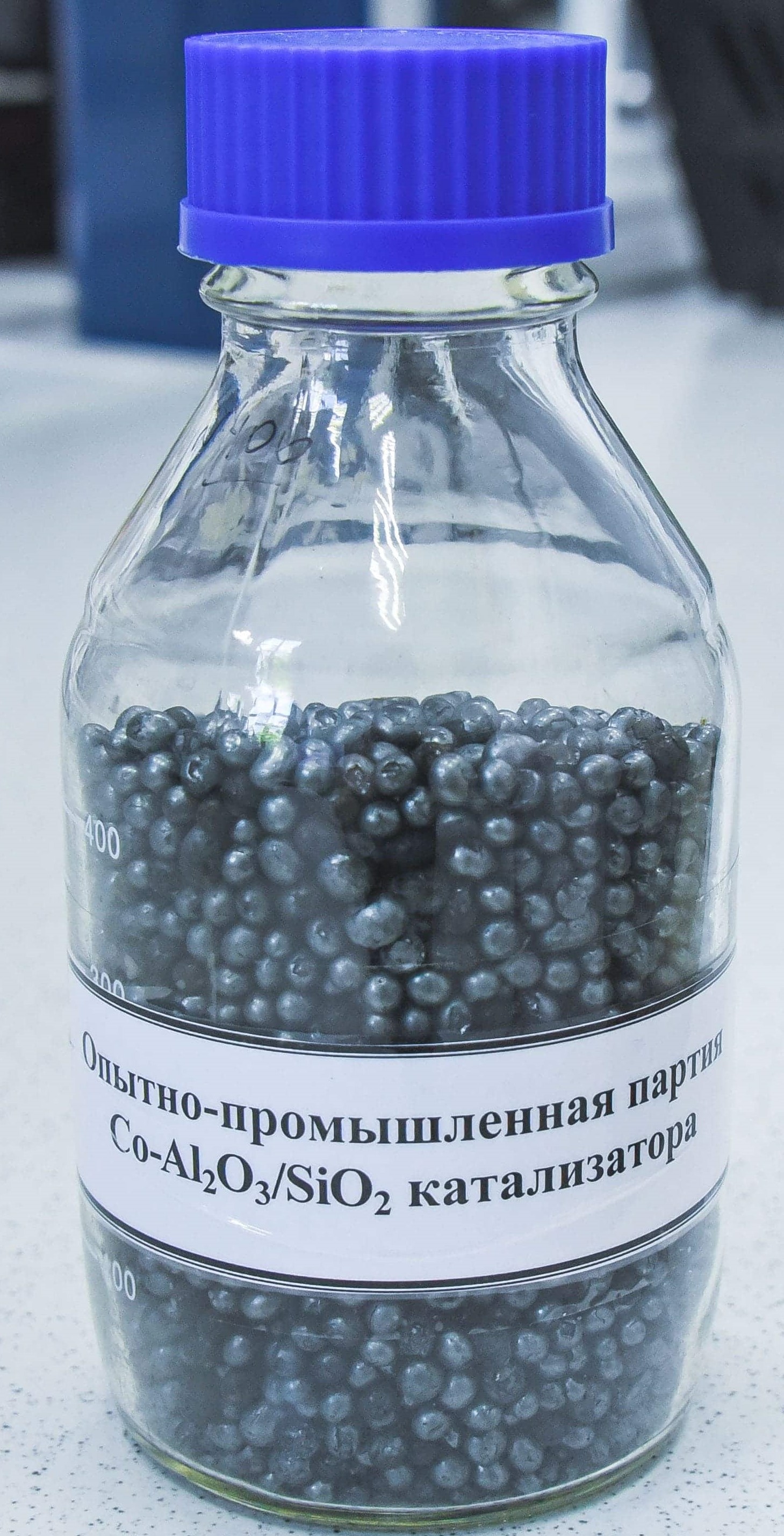

The synthesis of hydrocarbons from synthesis gas is carried out on a cobalt-silica gel catalyst developed at the Research Institute NTNM (TU No. 2174-001-02069125-2013).

The catalyst is characterized by:

- High selectivity for waxes (more than 60%);

- High productivity for C5+ hydrocarbons (180 kg/m3cat h);

- High stability of work (tested in long continuous runs under various loads and intensities).

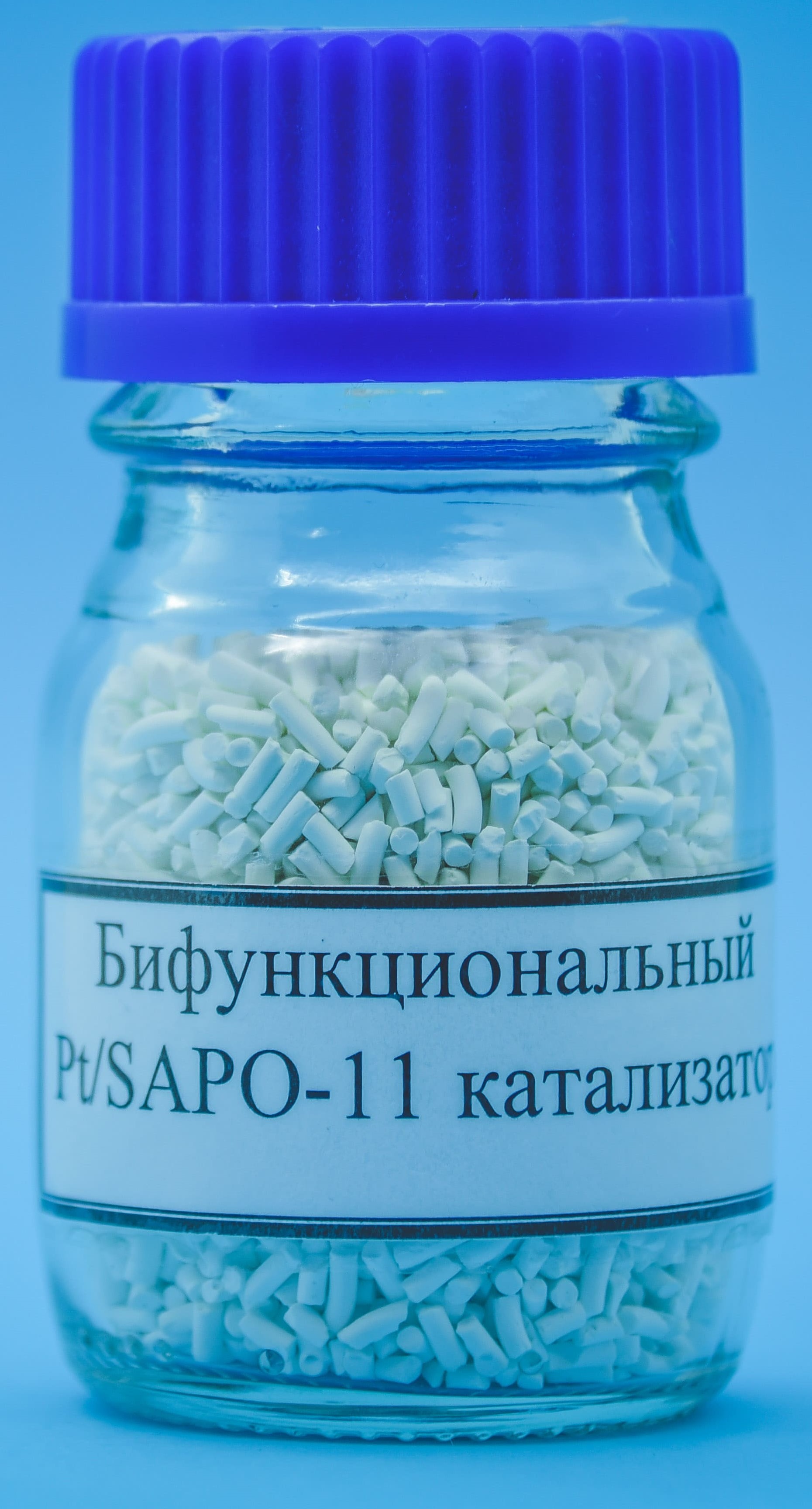

Hydrocracking and hydroisomerization of waxes to obtain group III+ isoparaffin oils is carried out on a bifunctional Pt/SAPO-11 catalyst with a hierarchical porous structure and high platinum dispersion. The catalyst was developed jointly with the Institute of Petrochemistry and Catalysis of the Russian Academy of Sciences.

Products

Ceresin synthetic brand 100

Synthetic ceresin is a mixture of solid hydrocarbons of the methane series of normal structure. In appearance, ceresin resembles beeswax in a light yellow or white color and is odorless. The areas of application of ceresin are diverse: it is used in the production of varnishes and varnishes, greases, in electrical engineering, in radio engineering, in electroplating, in the military-industrial complex for the production of phlegmatizers, as well as shoe creams, medical vaseline, various medicinal ointments, printing ink, in candle production, for the production of carbon wax paper, etc.

Isoparaffin oils III+ group

High-quality base oils of group III+ group are characterized by a high content of isoparaffins, the absence of sulfur compounds, unsaturated hydrocarbons. They have a high viscosity index, low pour point.

|

Index |

Test method |

Meaning |

|

Density at 20 °С, kg/m3 |

GOST 3900 |

802,5 |

|

Kinematic viscosity at 40 °С, mm2/s |

GOST 33 |

8,668 |

|

Kinematic viscosity at 100 °С, mm2/s |

GOST 33 |

2,558 |

|

Viscosity index |

GOST 25371 |

131 |

|

Pour point, °С |

GOST 20287 |

-18 |

Summer diesel fuel synthetic

Synthetic diesel fuel is a product of the distillation of a wide fraction of synthetic hydrocarbons, it is a mixture of volatile hydrocarbons consisting mainly of hydrocarbons of the methane series of normal and iso structure with a boiling temperature range of 200-350 ° C.

Recently, as part of improving environmental safety, the content of sulfur compounds in diesel fuel has been strictly regulated. Sulfur here refers to the content of sulfur compounds - mercaptans (R-SH), sulfides (R-S-R), disulfides (R-S-S-R), thiophenes, thiophanes, etc., and not elemental sulfur as such; R is a hydrocarbon radical. According to the latest standards of Europe and the state of California (diesel fuel grade EURO-5), the permissible sulfur content in diesel fuel is not more than 0.001% (10 ppm). Unlike petroleum, synthetic diesel fuel is practically free of sulfur (< 5 ppm) and polycyclic aromatic hydrocarbons (< 0.05%), which makes synthetic diesel. the fuel is more environmentally friendly, while increasing the cetane numbers of the fuel. However, a decrease in the sulfur content in diesel fuel, as a rule, leads to a deterioration in its lubricating properties; when using synthetic diesel fuel in road transport, it is recommended to use additives that increase the lubricating properties of the fuel.

|

Name of indicator |

Meaning |

|

Cetane number |

70 |

|

Density at 15°С, kg/m3 |

780 |

|

Sulfur content |

absence |

|

Mass fraction of polycyclic aromatic hydrocarbons, % |

absence |

|

Limiting filterability temperature, °С |

+5 |

|

Flash point, determined in a closed crucible, °С, |

60 |

|

Copper strip test at 50°C, 3 hours. |

Withstands |

|

Ash content, %, no more |

0,0001 |

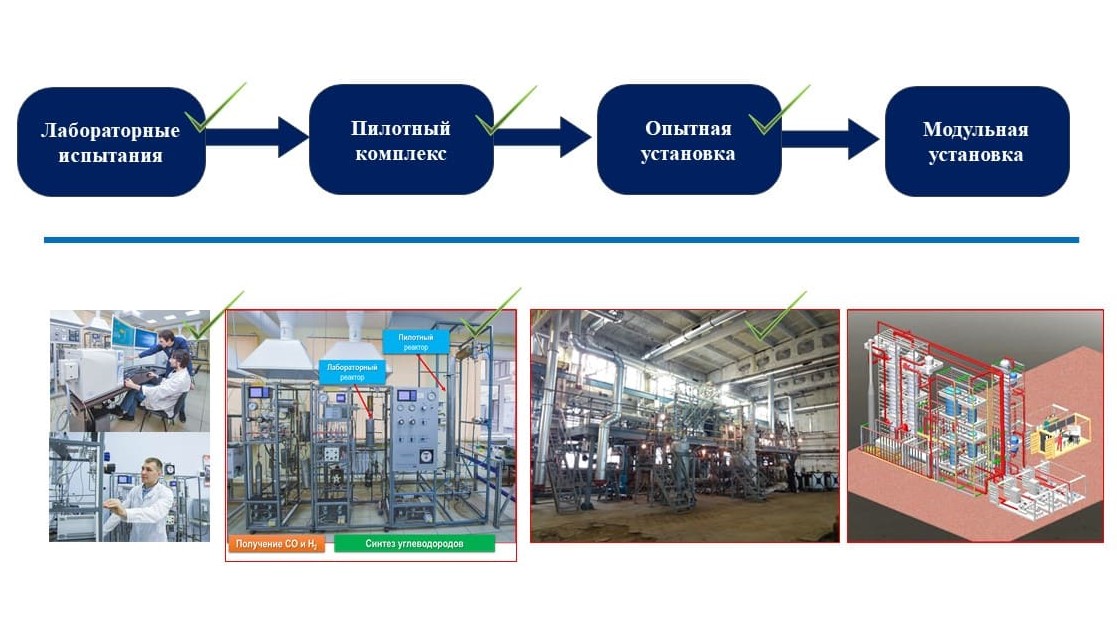

Implementation of technology in industrial conditions

The team of NII NTNM developed a pilot plant for the production of synthetic solid hydrocarbons (ceresin) from natural gas for the Ya.M. Sverdlov, Dzerzhinsk, Nizhny Novgorod region.

The technological scheme of the process includes three stages: production of synthesis gas, synthesis of a wide fraction of hydrocarbons, isolation and purification of ceresin. The manufacture of equipment, its hydraulic and pneumatic tests were carried out at domestic machine-building enterprises.

Process regulations and specifications (No. 2174-001-02069125-2013) for cobalt catalyst have been developed. CJSC "Samara Catalyst Plant" produced a pilot batch of catalyst with a volume of 1 m3.

The pilot plant allows you to work out technological regimes and obtain initial data for the design of a full-scale industrial plant for the synthesis of liquid and solid hydrocarbons, which will contribute to the further development of the domestic industry for the production of synthetic hydrocarbons from carbonaceous raw materials.

Our strategy