Light GTL

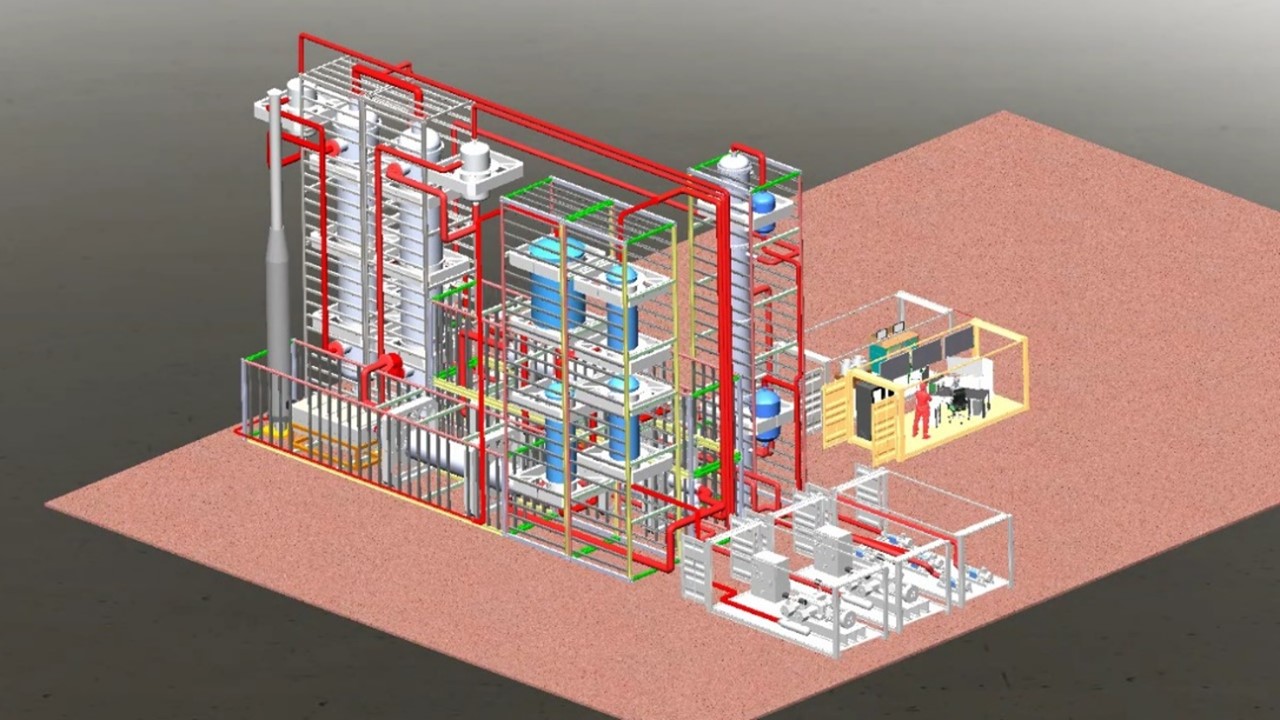

NTNM Research Institute has developed an effective technology for obtaining light synthetic oil and products based on it (gasoline, kerosene, diesel fuel) from natural and associated petroleum gases - Light GTL.

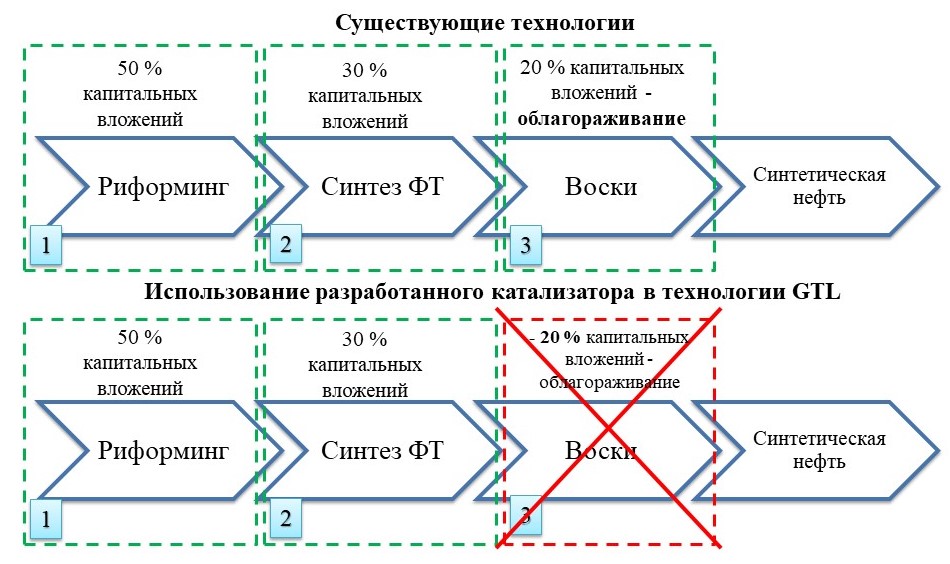

The use of an efficient hybrid catalyst in the technology makes it possible to reduce the number of stages in production and reduce capital and operating costs.

Key features of the technology:

- New technological solutions at the stage of gas reforming, allowing the use of natural and associated petroleum gas of variable composition;

- A new commercial hybrid catalyst for hydrocarbon synthesis, which makes it possible to obtain light synthetic oil of premium quality;

- Compatibility of the received products with natural oil;

- Possibility of obtaining commercial arctic diesel fuel and aviation kerosene;

- Low capital and operating costs for the creation and operation of production.

Catalysts

At the stage of synthesis gas production, catalysts of one of the leading Russian developers and manufacturers of highly efficient catalysts for the chemical, petrochemical, metallurgical, food and other industries - NIAP-KATALYZATOR LLC, are used. Catalysts are designed for oxidative, steam, steam-carbon dioxide, steam-air and steam-oxygen conversion of hydrocarbon feedstock and natural gas.

At the stage of hydrocarbon synthesis, a new commercial hybrid hydrocarbon synthesis catalyst (TU 20.59.56.15-001-02069125-2018) is used, which makes it possible to obtain premium quality light synthetic oil. At present, a pilot batch of the catalyst has been manufactured jointly with LLC Ishimbay Specialized Chemical Plant of Catalysts (ISCPC).

The catalyst is characterized by:

- High productivity on С5+ hydrocarbons (up to 180 kg/m3kat h);

- High selectivity for hydrocarbon fuel fractions (up to 100%);

- The possibility of obtaining arctic diesel fuel of class K5;

- The stability of the main indicators of the process in long-term continuous tests;

- Possibility of "tuning" the selectivity of the process by changing the parameters of the processes.

Products

Gasoline fuel

Synthetic gasoline fuel is a product of the distillation of a wide fraction of synthetic hydrocarbons, it is a mixture of volatile hydrocarbons consisting mainly of hydrocarbons of the methane series of normal and iso structure with a boiling temperature range of 30-200 ° C.

Recently, as part of improving environmental safety, the content of naphthenic, aromatic and unsaturated hydrocarbons, as well as impurities of sulfur and nitrogen-containing compounds, has been strictly normalized in its composition.

Performance characteristics of gasoline fuel

|

Наименование показателя |

Метод испытания |

Значение |

|

Octane number |

GOST R 52947 |

78,5 |

|

Density at 15 °С, kg/m3 |

GOST R 51069 |

710,2 |

|

Net calorific value, kJ/kg |

GOST 21261 |

43780 |

|

Acidity, mg KOH per 100 cm3 of fuel |

GOST 5985 |

66,18 |

|

Iodine number, g of iodine per 100 g of fuel |

GOST 2070 |

11,8 |

|

Saturated vapor pressure, kPa |

GOST 33157 |

41,2 |

|

Fractional composition, % vol.: at a temperature 70 °С 100 °С 150 °С end of boiling, °C Volume fraction of the residue in the flask, % vol. |

|

10,2 39,4 84,7 185,5 1,0 |

Diesel fuel arctic

In connection with the intensive development of the Arctic, the issue of providing consumers with high-quality low-solidification diesel fuel is especially acute for Russia. The output of this type of fuel in the Russian Federation should be at least 30% of the total production of diesel fuel, but the actual volume of its production does not exceed 17%.

Arctic diesel fuel can be obtained from associated petroleum gas using the GTL technology of NTNM Research Institute in oil production areas. This technology will make it possible to utilize APG, produce high-quality fuel that outperforms oil counterparts in terms of operational and environmental performance, and reduce the shortage of this type of product in the regions.

Comparative characteristics of synthetic diesel fuel with the requirements of GOST R 55475-2013

|

Name of indicator |

Value according to GOST R 55475-2013 |

Actual value |

||||

|

А-44 |

А-48 |

А-52 |

||||

|

Cetane number |

47,0 |

51 |

||||

|

Cetane index |

43,0 |

63 |

||||

|

Density at 15 °С, kg/m3 |

800,0-855,0 |

777,0 |

||||

|

Mass fraction of polycyclic aromatic hydrocarbons, % no more |

8,0 |

0,0 |

||||

|

Mass fraction of sulfur, mg/kg no more К3 К4 К5 |

350,0 50,0 10,0

|

0,0 |

||||

|

Flash point in a closed crucible, °С, not lower |

30 |

57 |

||||

|

Ash content, % wt., no more |

0,01 |

0,0046 |

||||

|

Kinematic viscosity at 40 °С, mm2/s |

1,200-4,000 |

1,489 |

||||

|

Fractional composition: distilled to a temperature of 180 °C, % vol., no more 95% vol. distilled at temperature, °С, not higher |

10

360 |

3,5

290 |

||||

|

Cloud point, °С, not higher |

-34 |

-38 |

-42 |

-34 |

||

|

Limiting filterability temperature, °С, not higher |

-44 |

-48 |

-52 |

-45 |

||

Kerosene (jet) fuel

Kerosene (jet) fuel is the middle distillate fraction of oil hydrocarbons, boiling off at a temperature of 140-280 °C.

The NTNM Research Institute has developed a technology for producing jet fuel, which consists in the isomerization of a 140–250 °C synthetic hydrocarbon fraction on a bifunctional Pt/SAPO-11 catalyst with a hierarchical porous structure and high platinum fineness. This catalyst was developed jointly with the Institute of Petrochemistry and Catalysis of the Russian Academy of Sciences (Ufa, Bashkortostan).

Performance indicators of kerosene fuel

|

Indicators |

Normative documents |

Norm for RT |

Actual value |

|

Kinematic viscosity, mm2/s at 20 °C |

GOST 33 |

Not less than 1,25 |

1,497 |

|

Acidity, mg KOH per 100 cm3 of fuel |

GOST 5985 |

0,2-0,7 |

0,64 |

|

Iodine number, g of iodine per 100 g of fuel |

GOST 2070 |

No more 0,5 |

0,2 |

|

Crystallization start temperature |

GOST 5066 |

No more -55 |

Minus 67 |

|

Volume (mass) fraction of aromatic hydrocarbons, % |

GOST R 52063 (GOST 6994) |

No more 20(22) |

0,5 (0,6) |

|

Mass fraction of total sulfur, % |

GOST 19121 |

No more 0,10 |

2,4 (ppm) |

|

Copper strip test at 100°C for 3 hours |

GOST 6321 |

Withstands |

Withstands |

|

Metal content, %: -vanadium - cobalt - molybdenum |

STO 08151164-041-2010 |

|

Absence Absence Absence |

|

Thermal-oxidative stability under static conditions at 150°С: a) sediment concentration, mg per 100 cm3 of fuel b) concentration of soluble resins, mg per 100 cm3 of fuel c) concentration of insoluble resins, mg per 100 cm3 of fuel |

GOST 11802 |

No more than 6

|

Отс.

5,6

Отс.

|

|

Net calorific value, kJ/kg |

GOST 21261 |

At least 43120 |

44100 |

|

Fractional composition: a) distillation start temperature, °C b) 10% is distilled off at a temperature, °C c) 50% is distilled off at a temperature, °С d) 90% is distilled off at a temperature, °С e) 98 is distilled off at a temperature, °C f) distillation residue, % g) losses from overclocking, % |

GOST 2177 |

135-155 Not higher than 175 Not higher than 225 Not higher than 270 Not higher than 280 No more than 1.5 Not more than 1.2 |

143 160 188 236 266 1,2 0,2 |

|

Density at 20°С, kg/m3 |

GOST 3900 |

At least 775 |

746,9 |

|

Flash point, determined in a closed crucible, ° С |

GOST 6356 |

Not less 28 |

32 |

Technology Implementation

The technology has been tested on laboratory and pilot equipment. Further work is aimed at creating a modular plant for processing APG into synthetic oil.