Description

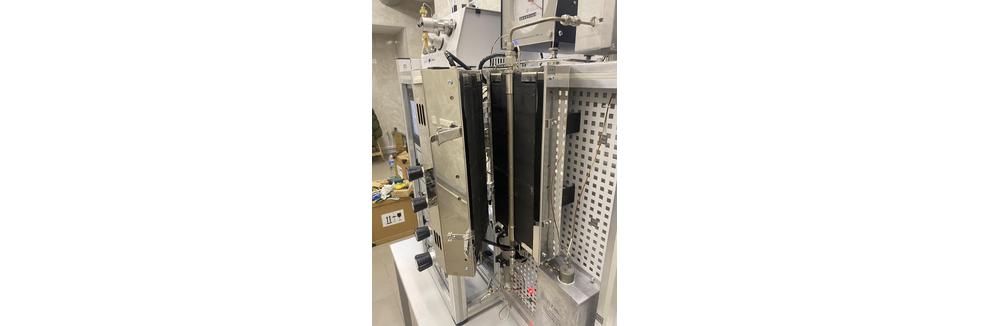

Catalytic lab-scale flow-through unit "FTU" is an automated unit based on a fixed-bed mini-reactor with a volume of up to 1.5 cm3. Desktop laboratory setup PU is designed to perform kinetic studies, evaluate the properties of catalysts, simulate catalytic processes, test the stability of catalysts and sorbents.

For maximum customer satisfaction, the unit has a modular design that can be expanded with additional options.

Main advantages:

- Compactness;

- Control of parameters in real time;

- Ease of maintenance;

- Operational safety;

- Convenient user interface.

Applied tasks:

- Hydrocarbon hydrogenation/dehydrogenation processes;

- Fischer-Tropsch synthesis;

- Catalytic cracking and isomerization;

- Reforming of natural gases;

- Hydrogenation processes;

- Catalytic oxidation;

- Hydrotreating processes.

Basic completeness:

- Gas supply unit;

- Reactor block;

- Separation unit;

- Sampling unit;

- Unit for measuring the volume of outgoing gas;

- Control block.

Specifications

General installation information

|

Installation weight, no more than kg |

40 |

|

Overall dimensions of the installation, no more than mm |

720×710×550 |

|

Installed power supply, kW |

4,0 |

|

Volume of a tubular reactor with a fixed catalyst bed, cm3 |

5,0 |

|

Maximum working pressure, MPa |

10,0 |

|

Maximum operating temperature, °С |

400 |

|

The volume of the loaded catalyst, cm3 |

1-1,5 |

|

Communication with a computer (sensor monoblock) via Ethernet interfaces |

USB, RS232 |

Control block

|

Monitoring and control of process parameters |

Software, SCADA scheme |

|

Displaying parameters online |

SCADA diagram |

|

Recording Process Parameters |

Data archiving |