Description

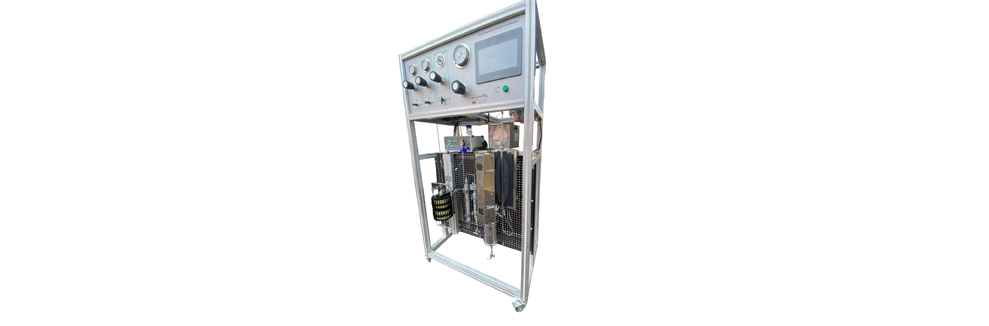

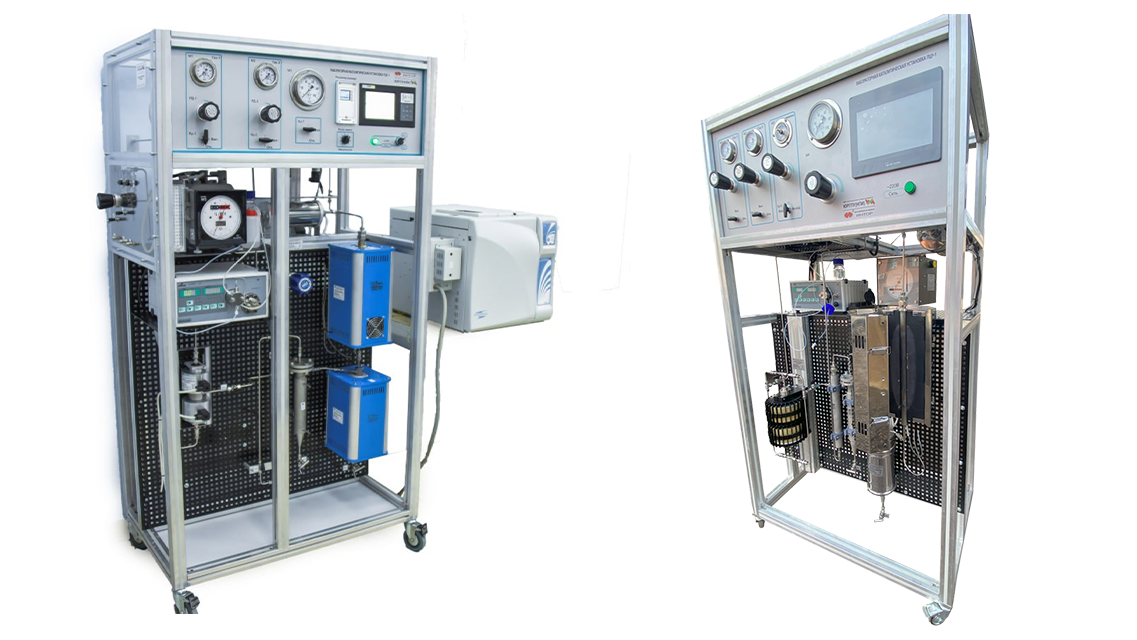

Catalytic lab-scale unit with gas-recycle mode "FCU-1" is designed to solve the following tasks:

- Educational and scientific research of chemical processes;

- Improvement of existing and development of new industrial processes;

- Studies of homogeneous and heterogeneous catalysts.

Catalytic lab-scale unit with gas-recycle mode "FCU-1" is manufactured in accordance with the technical requirements of the customer for operation in a wide range of technological parameters. Additional built-in equipment is designed to control the flow of raw materials and products, as well as collect and process data. The installation is distinguished by the possibility of subsequent modernization for new purposes.

Main advantages:

- Reliable and high-precision system of control and regulation of technological parameters;

- Ease of replacement of catalyst samples;

- The possibility of conducting long-term tests in continuous mode;

- The possibility of modernizing the design for new purposes;

- The possibility of testing in flow and flow-circulation modes;

- Control and precise reproduction.

Applied tasks:

- Hydrocarbon hydrogenation/dehydrogenation processes;

- Fischer-Tropsch synthesis;

- Catalytic cracking and isomerization;

- Reforming of natural gases;

- Hydrotreating processes.

Completeness (the final delivery set depends on the terms of reference):

- Gas supply unit;

- Liquid feed unit;

- Block of heating and evaporation of raw materials;

- Reactor block;

- Cooling, separation and drying unit;

- Gas circulation unit;

- Sampling unit;

- Unit for measuring the volume of outgoing gas;

- Control block.

Specifications

General installation information

|

Installation weight, no more than kg |

150 |

|

Overall dimensions of the installation, no more than mm |

1000×600×1750 |

|

Installed power supply, kW |

4,0 |

|

Volume of a tubular reactor with a fixed catalyst bed, cm3 |

100 |

|

Maximum working pressure, MPa |

10,0 |

|

Maximum operating temperature, °С |

700 |

|

The volume of the loaded catalyst, cm3 |

5-50 |

|

Number of channels for gas supply, pcs. |

3 |

|

Circulation ratio, range |

1-100 |

|

Fluid flow, ml/min |

0,005-4,995 |

|

Maximum pressure at which liquid is supplied to the installation, MPa |

10,0 |

|

Communication with a computer via Ethernet interfaces |

USB, RS232 |

Control block

|

Monitoring and control of process parameters |

Software, SCADA scheme |

|

Displaying parameters online |

SCADA diagram |

|

Recording Process Parameters |

Data archiving |