Heterogeneous catalysis

Engineering

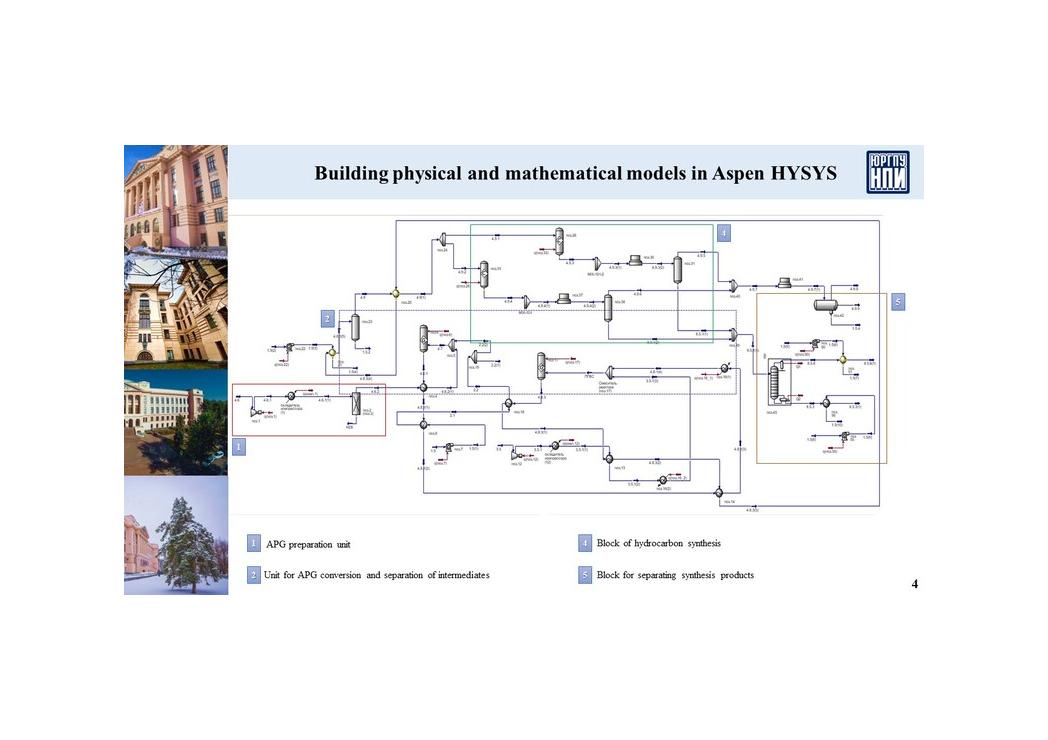

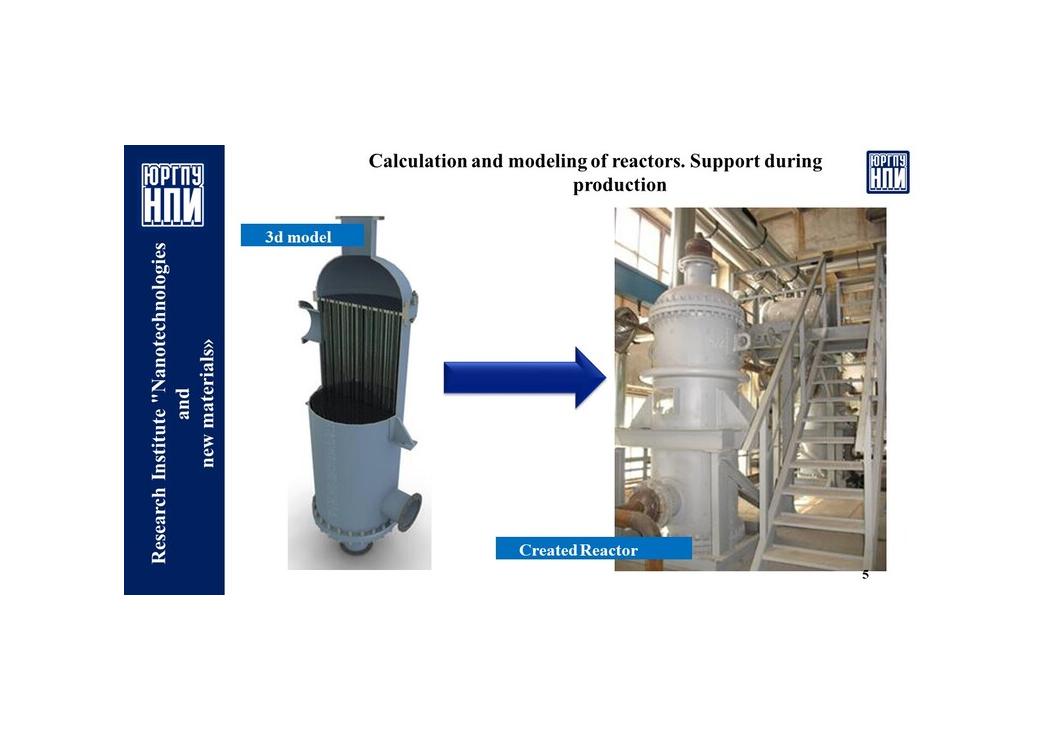

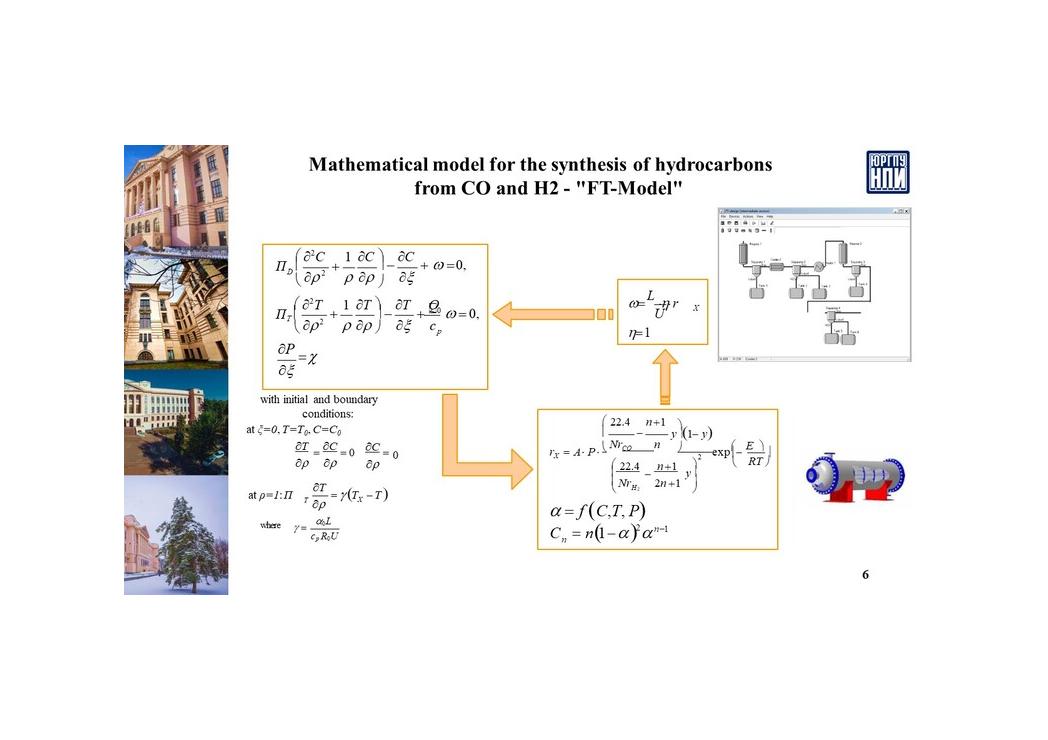

The Heterogeneous Catalysis Department performs a range of works on the development of new chemical technologies, including: conducting experimental studies, developing catalysts, scaling up technology, developing initial data for design, developing working design documentation, and supporting projects.

Technology Scaling

The Department of Heterogeneous Catalysis has the experience and a set of professional competencies to implement the technology on a laboratory, pilot and industrial scale. We can create a new chemical technology based on research and development, turn it into a serial and marketable product.

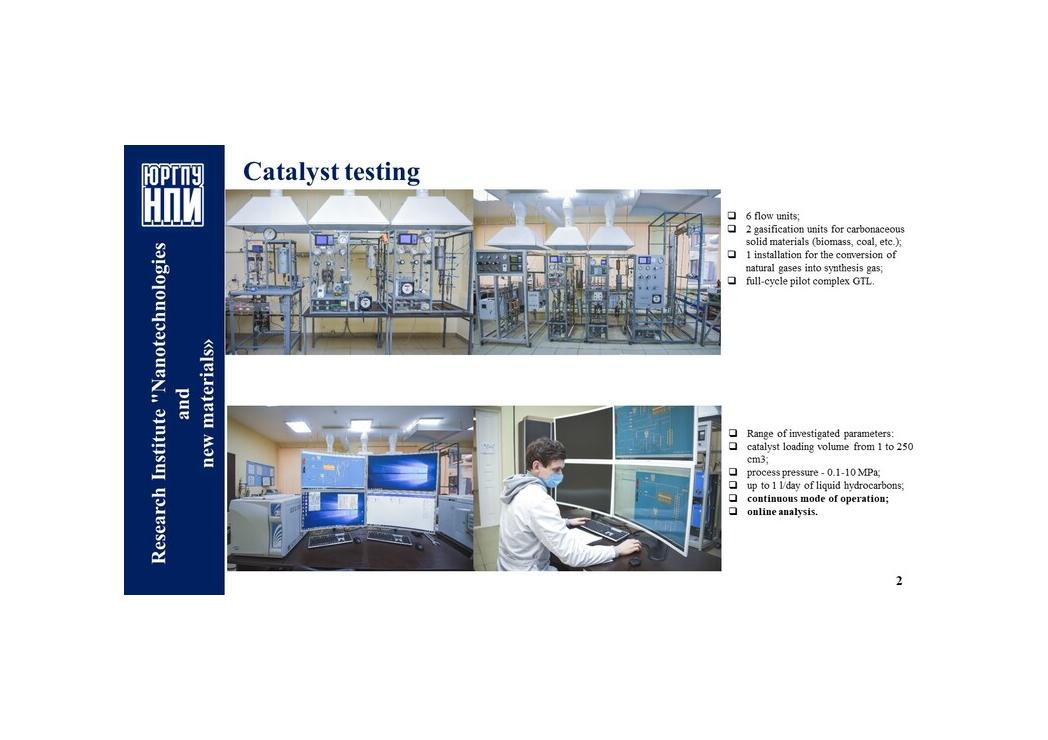

Our capabilities:

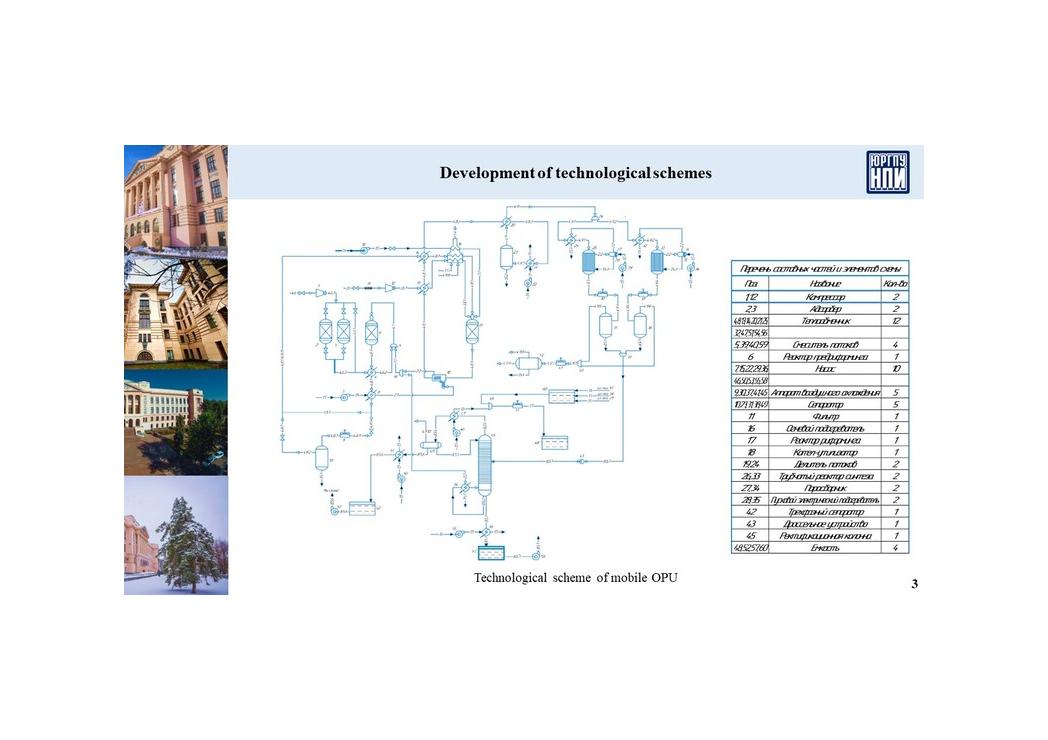

- Development of schemes for laboratory, pilot and experimental installations;

- Planning of experimental work;

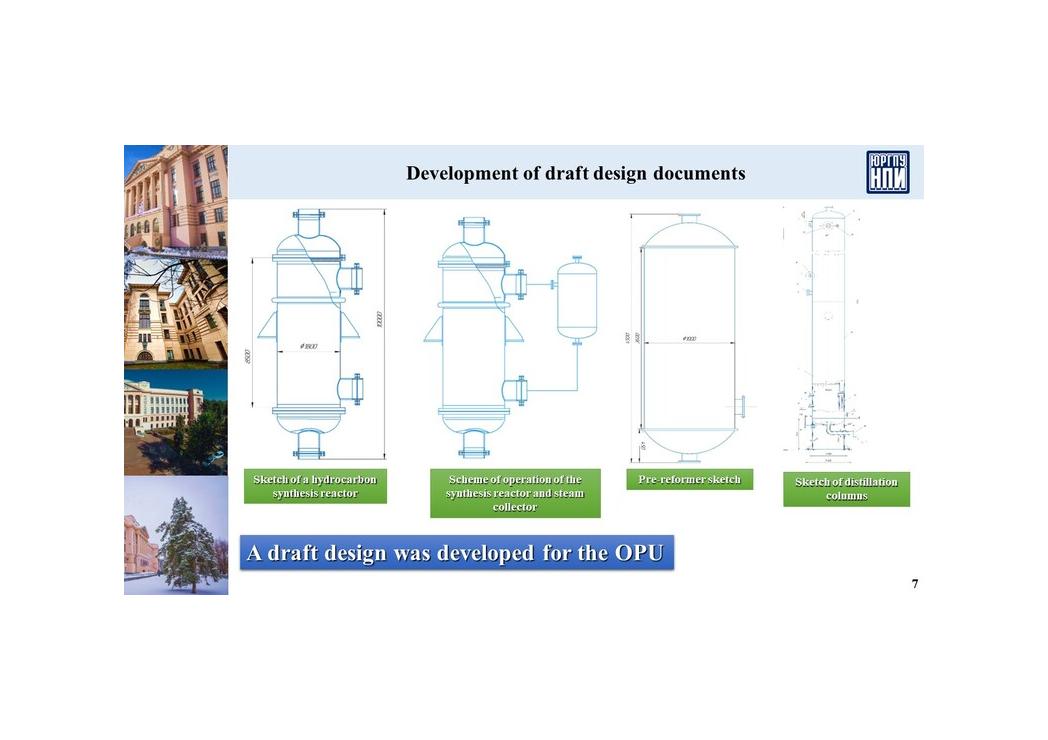

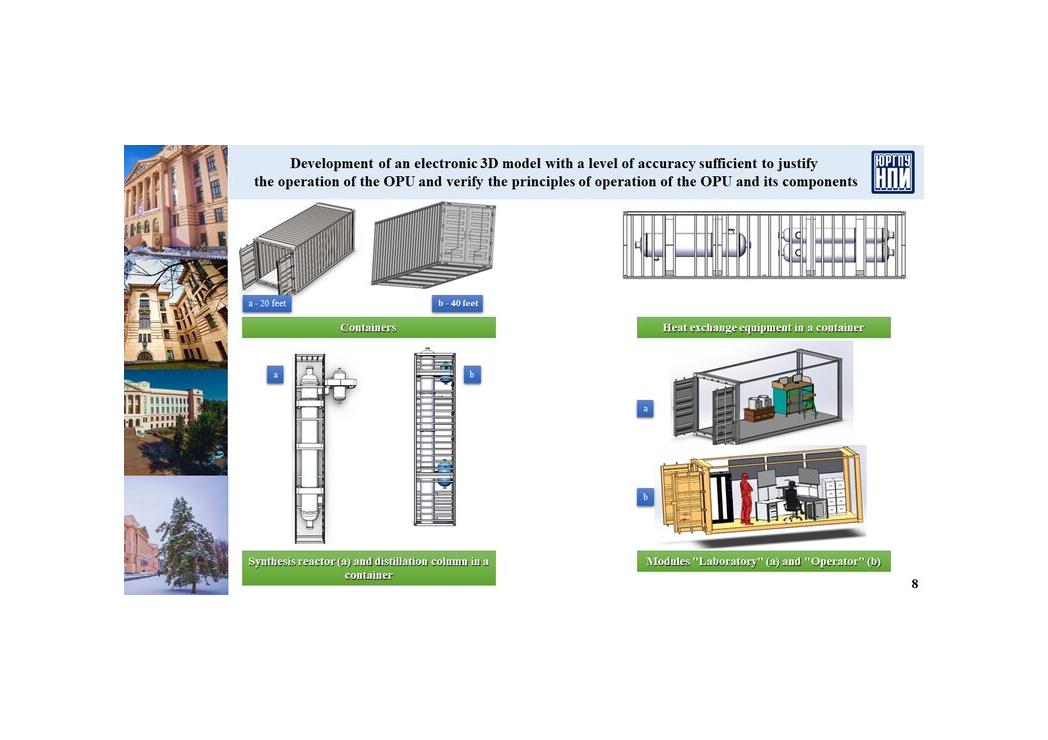

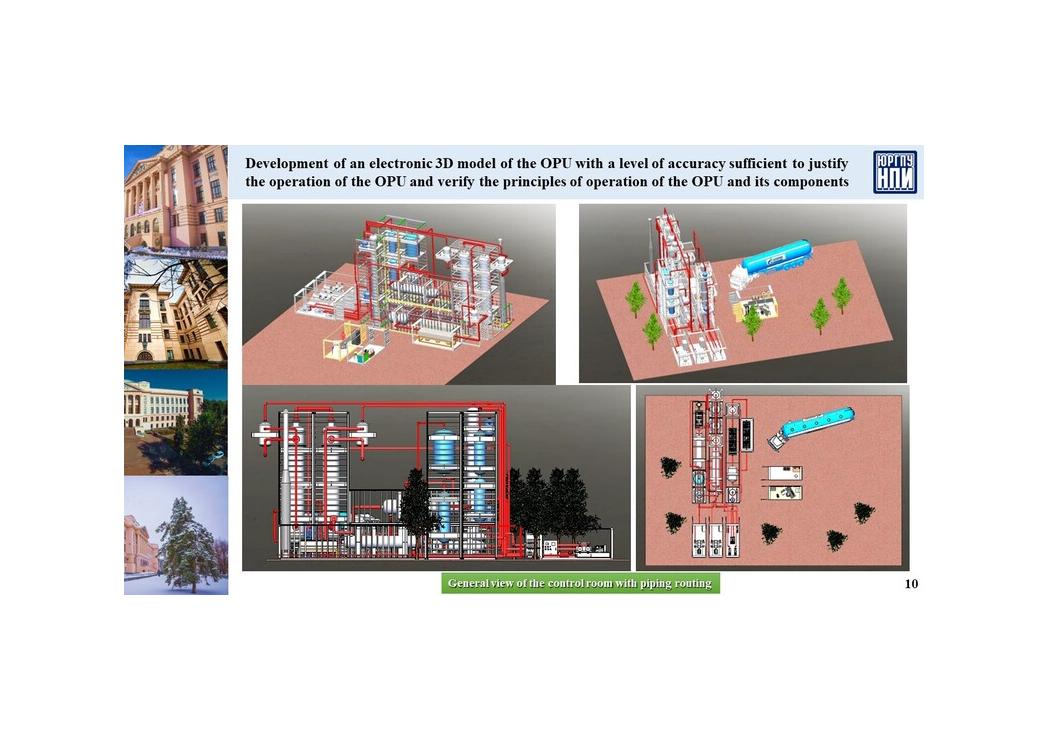

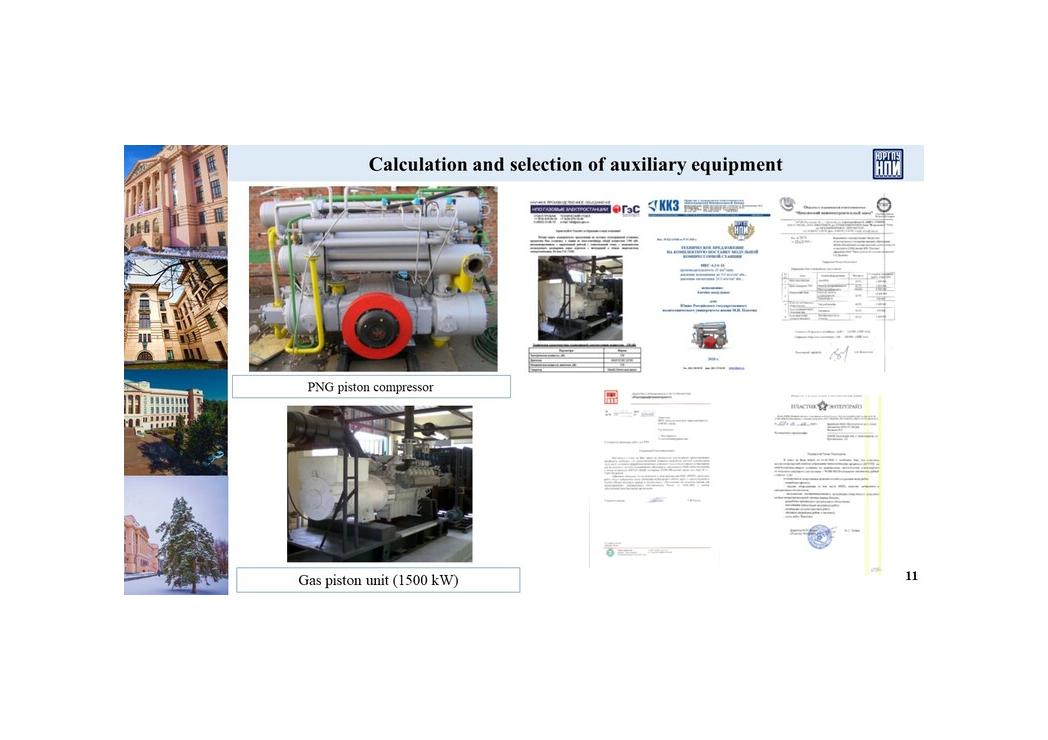

- Purchase of the necessary standard equipment, production of design documentation for non-standard equipment;

- Development of a process automation scheme;

- Recommendations for the preparation of the site, taking into account the special technological process;

- Operation of the plant in a given technological mode, production time, data collection and processing

Throughout the entire stage of technology scaling, data is collected, processed, and systematized on the progress of the technological process in order to clarify the set of parameters and eliminate the shortcomings of the identified problems.

Production support

The Heterogeneous Catalysis Department can provide a full range of services for technology selection and project implementation control on site.

Our tasks include monitoring, as well as providing consulting and methodological support, ensuring that the results of projects and reporting documents comply with the accepted requirements, as well as analyzing discrepancies and finding solutions to eliminate discrepancies.

As part of the provision of the Production Support service, we select technology, adapt it to the customer’s site and raw materials; control over the development of project documentation; organization of procedures for the purchase of materials and supply of equipment; carrying out installation and commissioning works; training.

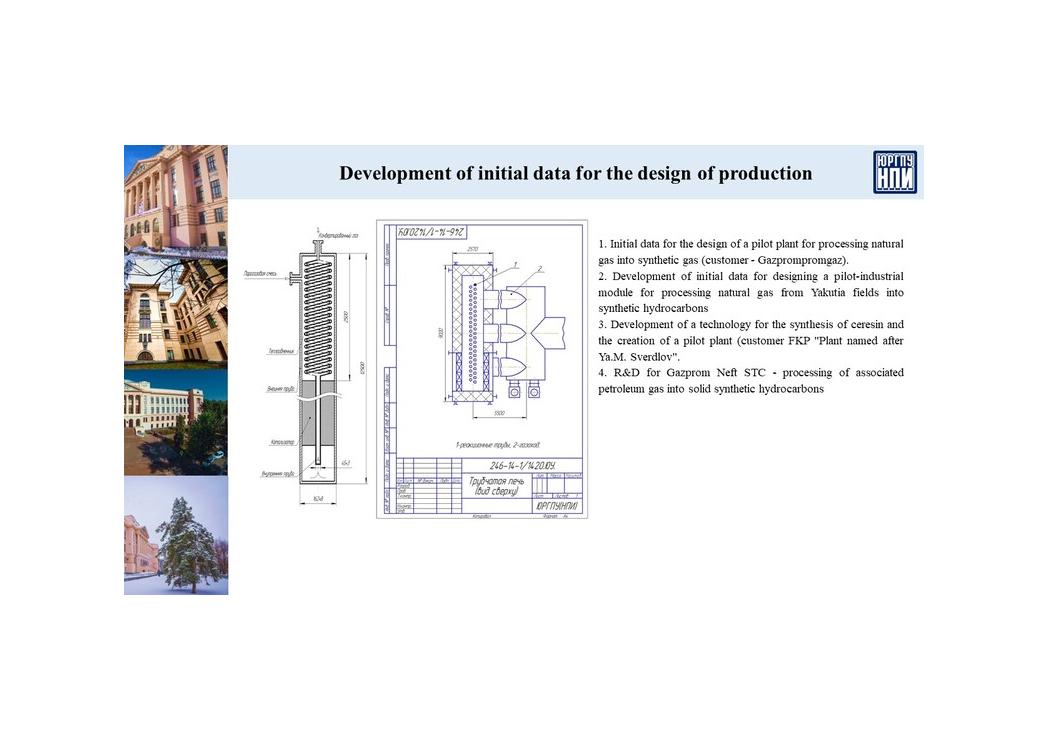

Development of technical documentation for enterprises of the chemical complex

Our department is developing an effective strategy for the development of a chemical enterprise, including the choice and justification of technologies for organizing production, taking into account the capabilities of the enterprise itself; market analysis taking into account the geography of location, raw material base, energy resources, potential consumers, etc.; development of initial data for design and working design documentation (description of the technological process and scheme for the production of the final product, layout of the potential customer on the existing infrastructure, industrial and environmental safety standards, process automation scheme with control points and main process parameters, calculations of the main and auxiliary equipment, a list of possible emergencies and rules of conduct in case of their occurrence and recommendations for their elimination, etc.)