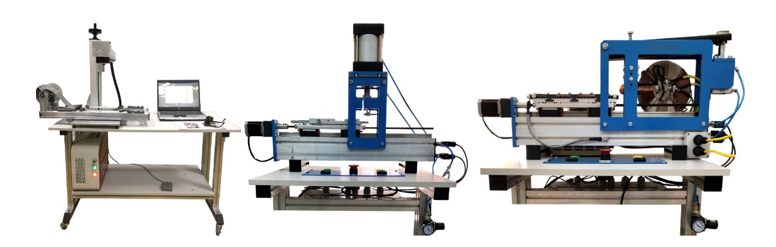

Complex of technological equipment for the manufacture of bipolar plates for ultralight fuel cells

The complex of technological equipment for the manufacture of bipolar plates for ultralight fuel cells includes laser cutting, forming and welding installations. The laser cutting machine is a laser machine with special equipment for cutting workpieces and technological holes. The molding unit includes a support frame with a plate on which a corrugating machine with strikers and equipment corresponding to the dimensions of the gas supply channel of the bipolar plate, a control unit and a stepper drive are installed. Clamping pressure is generated by a pneumatic cylinder. The installation for welding the cathode and anode parts of a bipolar plate consists of a table for welding, a worktop, an automated control system for the welding process, and a welding unit.

1. Installation of laser cutting. 2. Installation of molding. 3. Installation of automatic welding.

Using this complex of technological equipment, a power plant based on solid polymer fuel cells with a capacity of 1.5 kW was manufactured to participate in the UpGreat Technology Competition “First Element. Air" National Technology Initiative. The unit showed the best result in Russia - specific energy consumption of 529.3 W*h/kg.